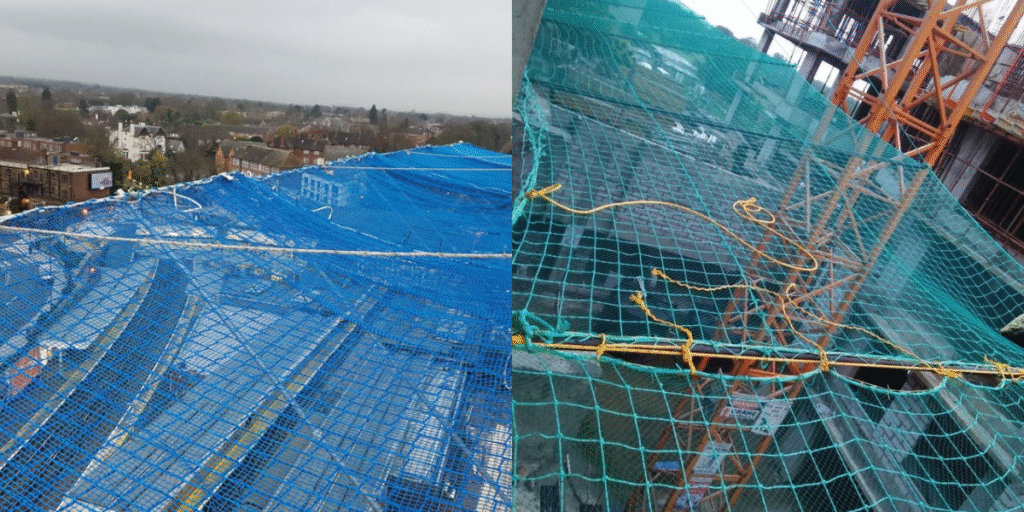

Horizontal Three layer Safety Nets

Introduction

Balaji Safety Projects provides workplace safety netting solutions for the roofing and construction industries. Additionally our product range encompasses Braided Safety Nets, Agro Shade Nets, Monofilament Nets / Scaffolding Nets, Anti Bird Net, Bird Spikes, Full Body Harness & Protective Equipments and ropes etc. We use good quality raw materials to make these safety nets and ropes. Since the establishment of the company, we regularly improvise on our existing range of products of safety nets in order to come up with products that stand high on performance and durability.

Safety should always come first in the fast-paced world of construction, where tall buildings aim for the stars and deadlines are a constant concern. Working at heights and the possibility of falling tools and debris are just two of the inherent concerns. Harnesses and hard hats are necessary, but they are only a portion of an all-encompassing safety plan. We are the best Horizontal Three layer Safety Nets Manufacturer.

The safety nets that offer a vital line of defense are the true heroes, frequently operating in the background in silence.Today, we will examine the Horizontal Three-Layer Safety Net, a particular type of fall prevention that is quite effective. This is a carefully thought-out solution that is intended to add a new degree of protection to any building site; it is not just another net.

What Makes a Horizontal Three-Layer Safety Net

The conventional single-layer safety net has been the standard for far too long. It has limitations even if it provides a minimum level of fall arrest. Concentrated impact can cause tearing, straining, or even a single-layer net to fail, particularly when it is subjected to the strain of a fall from a considerable height. This may be particularly true if the network is outdated, badly maintained, or improperly set up.

Furthermore, not all falling objects may be contained by a single-layer net. Smaller tools, garbage, or materials can still fall through the mesh, providing a major risk to workers and the general public below, even though it can catch a person. Many single-layer nets fall short in addressing this important problem. We are the best Horizontal Three layer Safety Nets Supplier.

Why Choose Balaji Safety Projects

- Unwavering Commitment to Quality: When it comes to safety, we don’t think there is any room for compromise. Only the best, UV-stabilized materials from reliable producers are used by us. Our three-layer nets are constructed from high-strength polypropylene (PP) and are intended to endure the severe Indian climate, guaranteeing their long-term performance and durability.

- Knowledge and Experience: Our staff of highly skilled and knowledgeable experts has extensive knowledge of construction and industrial safety. Our professionals make sure that every project satisfies and surpasses safety regulations, from a thorough site evaluation to the creation and installation of a personalized netting solution.

- Certification and Compliance: We are committed to fulfilling and exceeding all national and international safety standards. You may rest easy knowing that our products and installation methods meet industry standards for both performance and compliance.

- Tailored Solutions: We are aware that every building site is different. We don’t provide a solution that works for everyone. Rather, we collaborate directly with you to fully grasp your goals and offer a customized netting solution that meets the demands of your project, be it a warehouse or a high-rise structure.

- A Proven Track Record: A lengthy list of happy customers throughout India attests to our commitment to excellence. Positive reviews and a strong track record attest to our excellent client service, reliable solutions, and high caliber of work.

- Dedication to Innovation and Standards: We, along with the safety industry, are always changing. We constantly improve upon our current goods and keep abreast of emerging safety standards and technological advancements. Because our products are made to adhere to international safety standards, you may be sure that you are not only safe but also fulfill the strictest international requirements.

- Increased Productivity and Employee Morale Employees are more self-assured and effective when they feel safe and protected. They may concentrate on their work without having to worry about falling all the time when there is a sturdy safety net in place. This type of “collective protection,” as opposed to sometimes unwieldy personal fall arrest systems, safeguards all employees in a certain region without limiting their mobility.

- Observance of safety regulations Strict fall protection regulations are enforced by regulatory agencies such as OSHA in the United States and comparable organizations around the world. When placed and maintained correctly, horizontal safety nets are an essential part of a safety plan that complies with regulations. The three-layer technique frequently goes above and beyond the bare minimum, providing an additional degree of assurance that you are not just fulfilling but surpassing safety regulations.

- Superior Materials: Only the best materials that meet strict safety standards are used by us. Our nets are made to endure the harsh conditions seen on building sites and are long-lasting and UV-resistant.

Applications of Horizontal Three Layer Safety Nets

High-Rise Building Construction

- When working at multiple floors above ground, there is a constant risk of tools, equipment, or even workers falling. Safety nets provide a reliable safety barrier at each level of construction.

Bridge Construction

- Bridge projects are often carried out above rivers or valleys. Nets provide essential fall protection for workers operating at height or over water.

Industrial Maintenance

- Many industries need maintenance work in high or risky areas (like boiler units or power plants). Safety nets ensure the team is protected during such operations.

Stadium and Infrastructure Projects

- Large-scale infrastructure like stadiums, auditoriums, or metro stations requires large nets to cover vast open areas.

Residential and Commercial Repairs

- Balaji Safety Projects also provides safety nets for painting, window cleaning, façade repairs, and glass installations for apartments and commercial buildings.

Bridges and Flyover Projects

- These nets are used during the erection of bridges and flyovers where working at height is a constant challenge.

Industrial Plants & Warehouses

- In maintenance zones of oil & gas, steel, or chemical plants, safety nets provide necessary fall protection.

Power Plants and Substations

- Nets help prevent tools and hardware from falling into sensitive areas during maintenance.

Shipyards and Docks

- While working on large vessels or port structures, three-layer safety nets ensure worker safety.

Table Specifications Horizontal Three Layer Safety Net

| Feature | Specification |

|---|---|

| Product Name | Horizontal Three Layer Safety Net |

| Brand | Balaji Safety Projects |

| Net Material | High-Density Polypropylene (HDPE)/Nylon |

| Number of Layers | Three (Top, Middle, Bottom) |

| Mesh Size (Outer Layer) | 100 mm x 100 mm |

| Mesh Size (Middle Layer) | 30 mm x 30 mm |

| Twine Thickness | 2.5 mm to 6 mm (custom options available) |

| Support Rope | 12 mm Polypropylene |

| UV Protection | Yes (UV stabilized for long life) |

| Breaking Strength | 500 kg – 1000 kg |

| Fire Retardant | Optional on demand |

| Colour Options | Green, Yellow, Blue (custom on request) |

| Installation Support | Yes – On-site team available |

| Usage | Building Construction, Industrial Sites |

Benefits of Horizontal Three Layer Safety Net

- The most important advantage is Ultimate Fall Arrest Protection. By absorbing the energy of a fall, a three-layer net offers a dependable, high-strength safety barrier that dramatically lowers the chance of fatalities or major injuries. It allows employees to concentrate on their work without having to worry about falling all the time.

- Superior Debris Containment: Construction debris, falling tools, and equipment can be equally as deadly as a human falling. The debris net layer is revolutionary because it keeps these tiny things from falling to the ground and endangering other workers, cars, or pedestrians. This is particularly crucial in congested metropolitan settings.

- Improved Environmental Responsibilities and Site Cleanliness: The dust control layer keeps the building site neat and stops dust pollution. This is advantageous for the environment and the local community in addition to the health of the employees.

- Increases Employee Morale and Productivity: Employee morale rises when they feel safe and secure. Increased concentration, effectiveness, and general productivity result from this. A productive workplace is one that is safe.

- Observance of Safety Regulations: A safe workplace is required in India by laws such as the Building and Other Construction Workers Regulation of Employment and Conditions of Service Act, You can prevent penalties, legal problems, and project delays by using a high-quality safety net system, such as the three-layer option, which shows a dedication to these requirements.

- Long-Term Cost Savings: Although a three-layer net requires an initial investment, it ultimately results in cost savings. You can lower medical costs, workers’ compensation claims, and perhaps legal expenditures by preventing accidents. Additionally, it keeps your project on track and guards against damage to priceless tools and supplies.

- Long-Term Cost-Effectiveness: Although the initial outlay may appear substantial, a strong safety net system ultimately results in cost savings. It lowers costly expenses related to medical bills, compensation claims, project delays, and legal fees by preventing accidents.

- Versatility: Three-layer horizontal safety nets are not limited to high-rise structures. They are quite adaptable and can be utilized for a wide range of tasks, such as big roofing jobs, industrial warehouses, and bridges.

Types of Horizontal Three Layer Safety Net

1. Standard Construction Safety Nets

- Used in building construction, bridges, flyovers, and other vertical structures.

- Installed at multiple levels to ensure workers are protected during their shift.

- Comes with border ropes and corner loops for strong grip.

Best For: General high-rise construction sites.

2. Debris Netting with Three Layers

- Dense lower mesh prevents small debris like stones, nails, and tools from falling.

- Protects pedestrians, parked vehicles, and workers at ground level.

Best For: Urban construction zones, renovation projects.

3. Customized Safety Nets

- Designed according to client-specific dimensions and strength requirements.

- Options for flame-retardant or chemically resistant nets available.

Best For: Industrial factories, chemical plants, or unique architectural structures.

4. Scaffolding Safety Nets

- Specially designed for use around scaffolding structures.

- Acts as both a fall protection system and a privacy screen.

Best For: High-rise glass façade work, exterior plastering.

5. Green Building Nets

- Eco-friendly nets made from recyclable materials.

- Helps maintain green construction certifications.

Best For: LEED-certified or environment-conscious projects.

Conclusion

The selection of safety gear is crucial in the construction industry. The horizontal three-layer safety net is the unquestionably better option for any project that puts the health and safety of its employees and the general public first, even though single-layer nets have their place. It is an essential instrument for contemporary building due to its capacity to offer complete protection from falls, debris, and environmental variables.

Keep in mind that investing in safety is an investment in your success as you organize your upcoming endeavor. You can rely on Balaji Safety Projects to give you the greatest safety solutions available, including our state-of-the-art three-layer safety nets. Our goal is to assist you in creating a culture of safety as well as structures.