Monofilament Double Layer Safety Nets Manufacturer

Introduction

Balaji Safety Projects provides workplace safety netting solutions for the roofing and construction industries. Additionally our product range encompasses Braided Safety Nets, Agro Shade Nets, Monofilament Nets / Scaffolding Nets, Anti Bird Net, Bird Spikes, Full Body Harness & Protective Equipments and ropes etc. We use good quality raw materials to make these safety nets and ropes. Since the establishment of the company, we regularly improvise on our existing range of products of safety nets in order to come up with products that stand high on performance and durability.

Safety is a duty in today’s fast-paced industrial, infrastructure, and construction environments. The demand for dependable fall protection systems has increased dramatically, from high-rise buildings and bridges to warehouses, balconies, and industrial facilities. In order to protect people and property, a reputable manufacturer of monofilament double-layer safety nets, like Balaji Safety Projects, is essential. By providing premium, long-lasting, and standards-compliant monofilament double-layer safety nets that satisfy the changing safety requirements of contemporary projects, Balaji Safety Projects has made a solid reputation for itself in the safety net manufacturing sector. We are the best Monofilament Double Layer Safety Nets Supplier.

Understanding Monofilament Double Layer Safety Nets

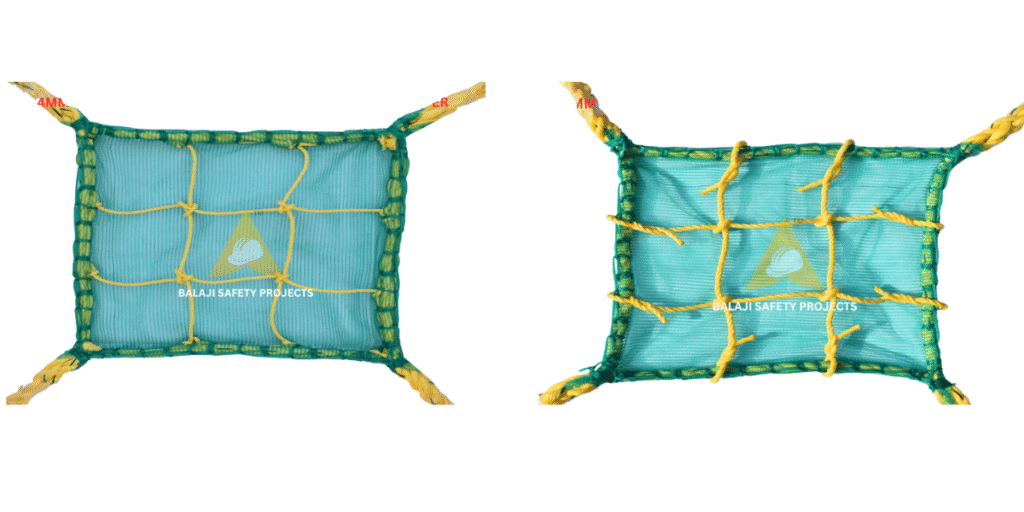

High-strength monofilament yarns are placed in two protective layers to create monofilament double-layer safety nets. Compared to single-layer nets, this dual-layer construction offers better shock absorption, increased load-bearing capacity, and superior protection against wear and tear. Balaji Safety Projects, a specialist manufacturer of monofilament double-layer safety nets, guarantees that every net is made to provide optimal safety, a long service life, and reliable performance even in challenging work environments. We are the best Monofilament Double Layer Safety Nets in Mumbai.

Why Choose Balaji Safety Projects

1. Industry-Proven Manufacturing

- Balaji uses high-grade monofilament yarns and controlled extrusion processes to guarantee consistent strength and durability across every roll. Our double-layer nets are manufactured with precision to ensure consistent mesh size, tension, and performance.

2. Certified Safety and Compliance

- We adhere to applicable national and international standards for safety nets. All products come with compliance documentation and test reports, helping site managers meet regulatory inspections without hassle.

3. Customisation and Design Support

- Projects aren’t one-size-fits-all. Balaji provides customised net dimensions, edge reinforcements, rope edging, and colour options suited to your site’s operational needs. Our engineering team can design bespoke anchoring solutions and installation layouts.

4. On-Site Consultation and Installation

- Beyond supplying nets, Balaji offers on-site consultation to ensure correct anchoring, appropriate safety factors, and professional installation. Proper installation is as important as the product itself — we make sure it’s done right.

5. Rapid Turnaround and Reliable Supply

- We maintain production capacity and inventory planning that supports both regular supply contracts and urgent one-off requirements. Clients appreciate our predictable lead times and batch traceability.

6. After-Sales Support and Lifecycle Management

- Balaji provides maintenance guidance, inspection checklists, and replacement schedules to maximise net life. If damage is found, our team helps evaluate repair vs. replacement based on safety priorities and costs.

7. Compliance with Safety Standards

- Balaji Safety Projects manufactures Monofilament Double Layer Safety Nets in line with industry safety norms and best practices. This helps clients meet regulatory requirements and improve their overall safety compliance.

8. Cost-Effective Safety Solutions

- While prioritising quality, the company also focuses on cost efficiency. Clients benefit from competitive pricing without compromising on safety performance, making Balaji Safety Projects a value-driven manufacturer.

9. Long-Term Durability & Reliability

- Thanks to UV-stabilised materials and robust construction, the safety nets maintain their strength and flexibility over time. This reduces replacement frequency and lowers long-term operational costs.

Applications of Monofilament Double Layer Safety Nets

1. Construction Sites

- Construction work often involves working at heights, where the risk of falls and injuries is significant. Monofilament double-layer safety nets are installed around scaffolding, building perimeters, and open areas to prevent accidental falls. These nets act as a safety barrier for workers, tools, and debris, reducing the chances of accidents and ensuring a safer working environment.

2. Industrial Facilities

- Industrial facilities, including manufacturing plants, warehouses, and factories, involve heavy machinery, high platforms, and potential falling hazards. Using double-layer safety nets in these settings helps protect workers from accidental falls and prevents equipment or objects from causing injuries.

3. Sports and Recreation Areas

- In sports arenas and recreational facilities, safety nets play a critical role in protecting athletes, spectators, and property. Monofilament double-layer nets are used in stadiums, playgrounds, and sports complexes to prevent balls or objects from flying into spectator areas, reducing injury risks.

4. Residential and Commercial Buildings

- Modern residential and commercial buildings often require safety nets during construction, maintenance, and façade cleaning. Double-layer nets ensure the safety of workers and passersby while preventing debris from causing damage to property.

5. Bridge and Highway Projects

- In large infrastructure projects, such as bridges and highways, safety nets are vital for preventing accidental falls and containing construction materials. The robust design of monofilament double-layer nets ensures that they can withstand significant weight and impact, providing a secure solution in high-risk areas.

6. Shipyards and Docks

- Shipyards, docks, and ports involve high platforms, cranes, and heavy cargo handling, making safety a top priority. Monofilament double-layer nets provide reliable protection for workers and equipment, reducing accidents during loading, unloading, and maintenance operations.

Table of Specifications Monofilament Double Layer Safety Nets

| Parameter | Specification |

|---|---|

| Material | Monofilament Double Layer Safety Nets |

| Design | Double Layer Mesh |

| Mesh Size | 50 mm x 50 mm (customizable) |

| Thickness | 2.5 mm – 4 mm |

| Breaking Strength | 350 – 500 kg per strand |

| Color | Blue, Yellow, Green, or Custom |

| UV Resistance | Yes, up to 5000 hours |

| Temperature Resistance | -40°C to +80°C |

| Certifications | ISO 9001, EN 1263-1/2 |

| Applications | Construction, Industrial, Sports, Bridges |

| Installation Method | Rope-laced, Hooked, or Custom Mounting |

Benefits of Monofilament Double Layer Safety Nets

1. Enhanced Worker Safety

- Worker safety is the top priority on any construction or industrial site. Monofilament double layer safety nets act as a protective barrier, preventing accidental falls from heights. The double-layer design ensures that even if one layer is breached, the second layer will catch the falling object or person, drastically reducing the risk of injury.

2. Protection Against Falling Debris

- Construction sites are prone to falling tools, bricks, and other materials. Installing monofilament double layer safety nets helps contain debris, protecting workers and bystanders below. This not only prevents injuries but also safeguards nearby property and machinery.

3. Durability and Longevity

- Monofilament fibers are highly resistant to environmental factors such as UV rays, moisture, and chemical exposure. This makes our double layer safety nets ideal for both indoor and outdoor applications. Their durability ensures they maintain strength and reliability over extended periods, reducing the need for frequent replacements.

4. Cost-Effective Safety Solution

- Investing in high-quality safety nets from Balaji Safety Projects is a cost-effective measure. By preventing accidents and equipment damage, companies save significantly on insurance claims, medical expenses, and operational downtime. The long lifespan of monofilament double layer safety nets further enhances their value for money.

5. Compliance with Safety Regulations

- Many industries and construction projects are required by law to implement safety measures for workers. Using certified monofilament double layer safety nets ensures compliance with these regulations, helping companies avoid legal penalties and maintain a safe working environment.

6. Easy Installation and Maintenance

- Balaji Safety Projects designs nets for easy installation without requiring extensive structural modifications. Additionally, monofilament double layer nets require minimal maintenance. Periodic inspections and basic cleaning are sufficient to ensure optimal performance.

7. Aesthetic and Flexible Design

- Despite their robust strength, these nets are lightweight and flexible, allowing them to be adapted to various architectural and structural layouts without compromising on aesthetics. Their unobtrusive appearance ensures safety without interfering with the operational or visual aspects of the project.

Types of Monofilament Double Layer Safety Nets

1. Construction Safety Nets

- Construction sites are among the most hazardous workplaces. Falling debris, tools, or materials can cause serious injuries to workers or bystanders. Construction safety nets are specially designed to protect labourers and property.

2. Sports Safety Nets

- Sports arenas, stadiums, and training centres require specialised safety nets to protect athletes and spectators. Balaji Safety Projects manufactures sports safety nets using monofilament double-layer technology, providing both durability and elasticity.

3. Industrial Safety Nets

- Industrial environments, including factories, warehouses, and production units, often have risks of falling objects. Industrial safety nets are designed to safeguard workers and equipment.

4. Fall Protection Nets

- Worker safety is paramount, especially at heights. Fall protection nets prevent injuries from accidental falls and are compliant with national and international safety standards.

5. Debris Catching Nets

- During construction, renovation, or demolition, loose debris can be hazardous. Debris-catching nets effectively prevent falling materials from causing damage or injuries.

6. Customised Safety Nets

- Balaji Safety Projects understands that not all safety requirements are standard. That’s why they offer customised safety nets, tailored to specific industrial, commercial, or recreational needs.

Conclusion

Safety in high-risk environments is non-negotiable, and Monofilament Double Layer Safety Nets provide a practical and effective solution for protecting lives and property. As a trusted manufacturer, Balaji Safety Projects excels in delivering robust, durable, and customizable safety nets that meet diverse industrial and recreational needs. From construction sites to sports facilities, these nets ensure maximum protection, compliance, and reliability. We are the best Monofilament Double Layer Safety Nets in Maharashtra.

Selecting Balaji Safety Projects entails selecting peace of mind, safety, and quality. You can be sure that your safety needs are in good hands thanks to their knowledge, cutting-edge production, and dedication to quality. The Monofilament Double Layer Safety Nets from Balaji Safety Projects are a model of innovation and protection for businesses and organisations seeking to invest in dependable safety solutions. To ensure a safe tomorrow, make sure you’re safe today.