Monofilament Safety Net Manufacturer

Introduction

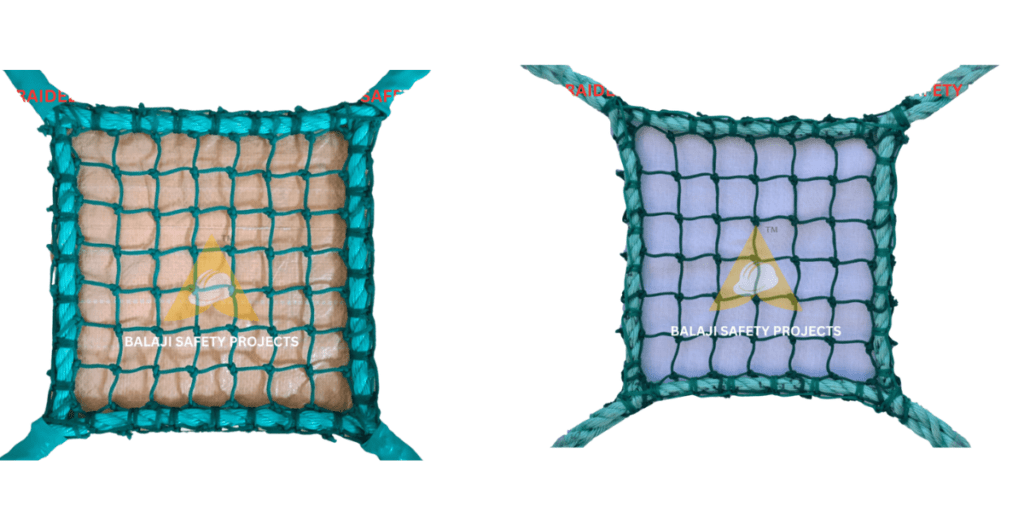

Balaji Safety Projects provides workplace safety netting solutions for the roofing and construction industries. Additionally our product range encompasses Braided Safety Nets, Agro Shade Nets, Monofilament Nets / Scaffolding Nets, Anti Bird Net, Bird Spikes, Full Body Harness & Protective Equipments and ropes etc. We use good quality raw materials to make these safety nets and ropes. Since the establishment of the company, we regularly improvise on our existing range of products of safety nets in order to come up with products that stand high on performance and durability.

The clang of steel, the boom of equipment, and the steady ascent of tall buildings are all commonplace in the busy world of construction. But in the middle of all of this activity, the safety net—an unsung hero—is silently working to protect both the public and employees. Furthermore, the monofilament safety net is unmatched in terms of dependability, toughness, and sheer protecting potential.”What’s so special about a monofilament net?” is a question you may have.

Let’s get started and discover the history of this essential piece of safety gear, including its uses, significance, and the reasons why should always pick a professional manufacturer like Balaji Safety Projects when safety is your top priority. We are the best Monofilament Safety Net Supplier.

What Exactly The Monofilament Safety Net

Consider a fishing line. Isn’t it thin, powerful, and nearly undetectable in water? Now picture innumerable lines of this kind interwoven to form a strong yet pliable mesh. That’s basically what a safety net made of monofilament is. Simply put, “monofilament” denotes “single filament.” These nets are built from single, solid strands of material, usually nylon or high-density polyethylene (HDPE), as opposed to nets produced from several twisted or braided strands. They have outstanding strength-to-weight ratios, superior UV resistance, and a variety of other qualities that make them perfect for safety applications because of their special construction. We are the best Monofilament Safety Net in Mumbai.

Why Choose Balaji Safety Projects

- Premium Monofilament Materials: We exclusively utilize the best HDPE and nylon monofilaments, which are renowned for their remarkable durability, tensile strength, and resistance to UV light. Our nets are made to endure severe weather, extended exposure to the sun, and heavy impact without deteriorating.

- Advanced Manufacturing Processes: Modern weaving and knotting methods are used to create our nets, guaranteeing consistent mesh size, sturdy construction, and optimal impact absorption. Each net is put through a thorough quality control process to ensure that it satisfies international safety standards.

- Reliability We recognize that a safety net is an investment in security. Because our nets are designed to withstand tearing, fraying, and environmental degradation, they will continue to function well for the duration of their useful lives.

- Experts in Customization: Every project has different needs. There is no “one-size-fits-all” strategy that we support. We design and manufacture nets to your exact specifications regarding size, mesh aperture, and load-bearing capability, whether you need them for a delicate home balcony, a large construction site, or a specialized industrial use.

- On-Site Evaluation and Discussion: Our skilled staff performs in-depth on-site evaluations to comprehend your unique safety concerns. After that, we offer professional guidance and suggest the best netting options based on your surroundings and legal requirements.

- Skilled and Trained Installers: The effectiveness of a premium net depends on how well it is installed. Our installation crews have received considerable training, certification, and experience in erecting safety nets in a variety of challenging locations. They follow the most stringent safety procedures.

- Secure and Compliant Fastening: Your nets will be firmly secured and able to support the desired load thanks to our use of strong and dependable fastening solutions. Our installations adhere to all applicable safety standards and industry best practices.

- On-time and Effective Service: We recognize the importance of project schedules. Our teams minimize operational disruption by working effectively and professionally to ensure timely installation.

- Beyond Just Sales: A transaction isn’t the end of our partnership with you. To keep your safety systems operating at their best, we provide continuing support, including guidance on upkeep, inspection, and replacement.

Applications of Monofilament Safety Net

- Possibly the most widely used application is debris containment. By preventing equipment, waste, and materials from falling and hurting workers or bystanders below, these nets provide an essential barrier around construction sites.

- Fall Protection: Monofilament nets can serve as an efficient secondary measure, greatly lessening the impact of a fall or catching workers who slip, even though they are not a primary fall arrest device on their own (always check safety standards.

- Surrounding Scaffolds: An extra degree of security is offered by enclosing scaffolding with netting, which keeps objects from falling through openings and offers some weather protection.

- Demolition Projects: These nets are essential for keeping dust, debris, and other airborne particles contained during demolition, safeguarding both the workers and the surrounding surroundings.

- Sports Enclosures: Monofilament nets are perfect for keeping balls contained and safeguarding spectators, whether they are used for cricket net enclosures or golf driving range obstacles.

- Gymnasium netting: establishing secure areas in gyms, including overhead netting to keep wayward balls away from ventilation or lighting systems.

Table Specifications Table Monofilament Safety Nets

| Specification | Details |

|---|---|

| Material | Monofilament Safety Net |

| Yarn Type | Monofilament |

| Mesh Size | 15mm to 100mm (customizable) |

| Color Options | Green, Blue, White, Black, Orange |

| UV Stabilization | Yes |

| Breaking Strength | 250 kg to 500 kg (depending on mesh size) |

| Roll Length | 50 meters to 100 meters |

| Width | 1 meter to 5 meters |

| Temperature Resistance | -30°C to +70°C |

| Usage Type | Reusable and Weatherproof |

Advantages of Monofilament Safety Nets

- Superior Sturdiness and Power: Don’t be fooled by the “single strand” claim. The tensile strength of monofilament threads, particularly those composed of HDPE, is remarkable. They are therefore quite effective in catching falling objects or persons because they can bear a lot of weight and force. Their durability, which withstands deterioration even under extreme environmental circumstances, is another factor in their extended lives.

- UV Resistance: The capacity of any outdoor safety device to endure extended exposure to sunshine is a crucial component. Because monofilament safety nets are naturally resistant to UV deterioration, they won’t deteriorate or break under the intense heat. This guarantees their durability and efficacy over time, which makes them perfect for sports enclosures, balcony netting, and outdoor building sites.

- Weatherproof and Rot-Proof: Synthetic monofilament materials are resistant to moisture, in contrast to natural fibers. They avoid rotting, mildew, and bacterial growth since they don’t absorb water. Because of this, they are ideal for any weather, from intense rain to high humidity, guaranteeing reliable performance and hygienic conditions.

- Lightweight and Simple to Install: Monofilament nets are remarkably light for their strength. Compared to more substantial netting options, this makes them simpler to handle, transport, and install. Additionally, less weight eases the strain on supporting structures, making installation easier and perhaps reducing labor expenses.

- Low Maintenance: Monofilament safety nets need less upkeep because of its ability to withstand weather and rot. Usually, all it takes to keep them clean and in working order is a quick wash with water, which ultimately saves time and money.

- Versatility in Application: Monofilament safety nets are extremely adaptable due to their strength, longevity, and resistance to weather. They are employed in.

Types of Monofilament Safety Nets

Nylon Monofilament Safety Net

- Made from high-quality nylon filament.

- Known for excellent strength and elasticity.

- Resistant to abrasion and chemicals.

- Used mostly in construction sites and industrial safety applications.

olypropylene Monofilament Safety Net

- Made from polypropylene material.

- Lightweight and cost-effective.

- Good resistance to UV rays and weather conditions.

- Commonly used in agriculture, bird control, and sports.

Polyester Monofilament Safety Net

- Manufactured using polyester filament.

- Strong and durable with low stretch.

- Excellent UV resistance.

- Suitable for outdoor safety, warehouses, and sports arenas.

HDPE (High-Density Polyethylene) Monofilament Safety Net

- Very high strength and durability.

- Resistant to chemicals, UV, and environmental damage.

- Used for heavy-duty industrial safety, cargo netting, and fall protection.

Conclusion

Safety simply cannot be compromised in the demanding surroundings of industry and construction. As a vital last line of protection against falls and falling items, monofilament safety nets are an essential equipment. Their transformation from straightforward obstacles to intricately designed fixes demonstrates the expanding recognition and significance of all-encompassing safety protocols. We are the best Best Monofilament Safety Net Manufacturer.

Selecting the appropriate manufacturer is crucial. In this crucial area, Balaji Safety Projects is a monument to excellence. They are the perfect partner for any firm that prioritizes safety because of their unwavering commitment to quality, innovative production techniques, wide range of products, and customer-focused attitude.